How UWB Technology is Revolutionizing Indoor Asset Tracking in 2026

Ultra-Wideband (UWB) tracking delivers centimeter-level accuracy indoors. Discover how UWB combined with RFID is transforming warehouse operations, manufacturing floors, and healthcare facilities.

The Rise of Ultra-Wideband in Industrial Asset Tracking

The demand for precise indoor positioning has never been higher. As warehouses grow larger, manufacturing lines become more complex, and hospitals need to locate critical equipment instantly, traditional tracking methods fall short. Enter Ultra-Wideband (UWB) — the technology delivering centimeter-level accuracy where GPS simply cannot reach.

Why UWB Matters Now

Unlike BLE beacons that offer room-level accuracy (3–5 meters), UWB achieves 10–30 centimeter precision using time-of-flight ranging. This leap in accuracy unlocks use cases that were previously impossible:

- Tool tracking on manufacturing floors: Know exactly which workstation a torque wrench is at, not just which building

- AGV navigation: Autonomous guided vehicles require sub-meter precision to safely navigate between racks

- Collision avoidance: Real-time worker-to-forklift proximity alerts that actually work

- Compliance zones: Verify that hazardous materials stay within designated areas

UWB + RFID: The Best of Both Worlds

At Intensecomp, we’ve learned that no single technology solves every tracking challenge. That’s why Inventrack 6.0 supports a multi-technology approach:

| Technology | Best For | Accuracy | Range |

|---|---|---|---|

| UWB | High-value tools, AGVs, personnel | 10–30 cm | 50–100m |

| Passive RFID | Bulk inventory, pallets, cases | Portal-level | 1–10m |

| BLE 5.0 | Zone presence, environmental sensors | 1–3m | 30–75m |

| LoRaWAN | Environmental monitoring, outdoor | Zone-level | 1–15km |

The key is deploying the right technology for each use case. A pharmaceutical warehouse might use RFID portals at dock doors, UWB tags on high-value temperature-sensitive shipments, and LoRaWAN sensors for cold chain monitoring — all feeding into one unified Inventrack dashboard.

Real-World Deployment: Automotive Parts Manufacturer

One of our automotive customers tracks over 12,000 specialized tools across three production halls. Before UWB, technicians spent an average of 18 minutes per shift searching for tools. After deploying Inventrack with UWB:

- Tool search time dropped to under 30 seconds

- Missing tool incidents decreased by 94%

- Production line downtime due to missing tools fell by 87%

- Annual savings exceeded SGD 1.2 million

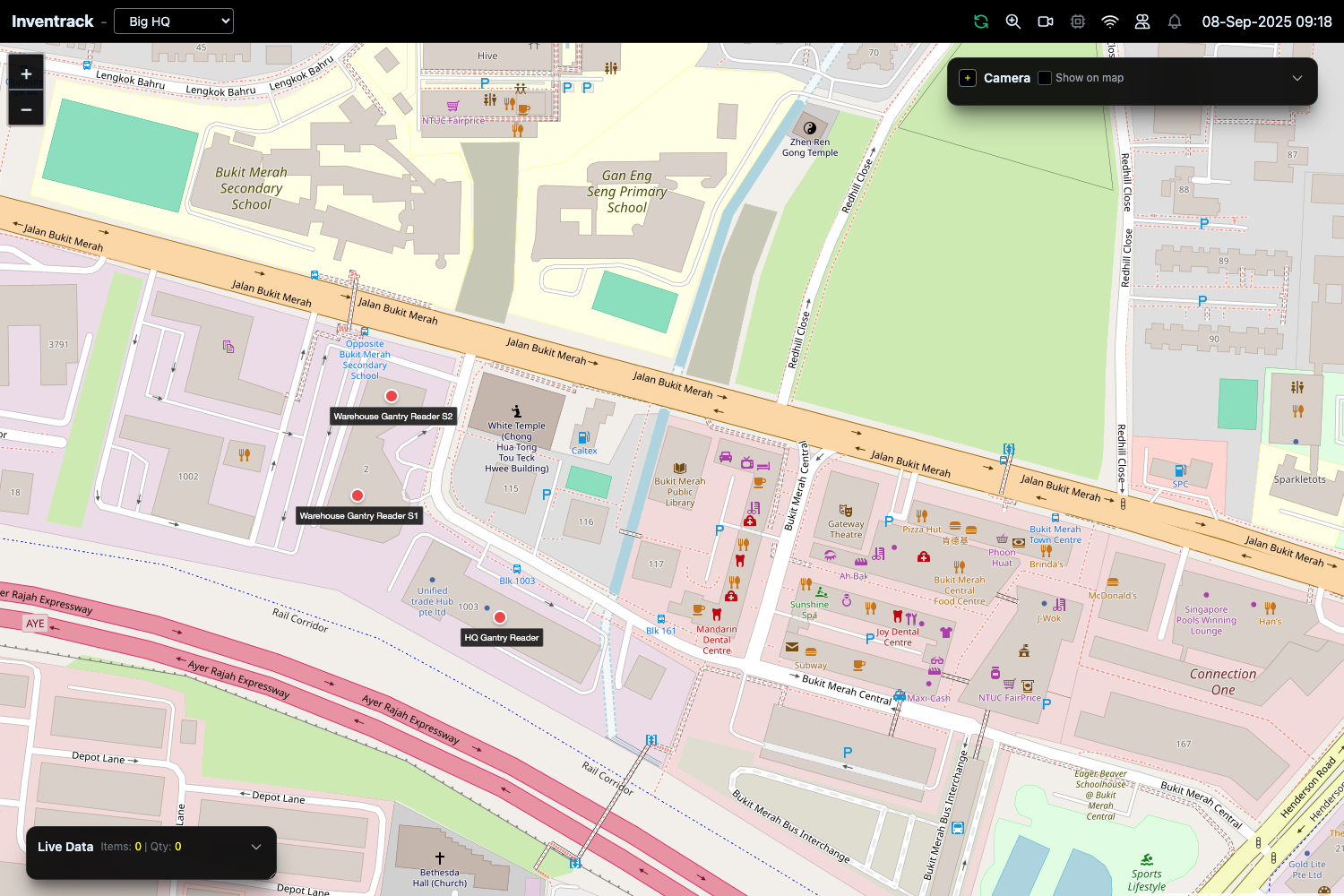

The UWB anchors were installed on the ceiling grid at 15-meter intervals, with small UWB tags attached to each tool. Inventrack’s 3D floor map shows the precise location of every tagged tool in real time, with movement history and geo-fence alerts.

Getting Started with UWB

Deploying UWB doesn’t require replacing your existing RFID infrastructure. Inventrack 6.0 treats all tracking technologies as inputs to a single asset intelligence layer. You can:

- Start small — pilot with 50–100 UWB tags in one critical zone

- Layer on existing RFID — keep your portal-based inventory tracking

- Scale gradually — add anchors and tags as ROI is proven

What’s Next

With the upcoming IEEE 802.15.4z standard gaining broader chipset support, UWB hardware costs are dropping rapidly. We expect UWB tags to reach price parity with active BLE beacons by late 2026, making centimeter-level tracking accessible for mid-market deployments.

If your operations demand precision beyond what RFID alone can deliver, UWB is no longer a futuristic proposition — it’s a proven, deployable solution today.

Want to see UWB tracking in action? Contact us for a live demo of Inventrack 6.0’s multi-technology tracking capabilities.

Ready to Transform Your Operations?

Discover how Intensecomp's RFID and IoT solutions can streamline your asset management.

Share this article

Related Articles

Walmart's Trillion-Dollar Bet: How Ambient IoT is Rewriting Supply Chain Rules

Explore how battery-free sensors and AI-driven automation are transforming warehouse operations, with Walmart deploying millions of sensors across 4,600 locations.

From Passive Tags to Intelligent Assets: How AI is Revolutionizing Warehouse Tracking

Explore how AI-powered IoT, LoRaWAN, and RFID technologies are transforming warehouse operations with 125M connected devices and $30B market growth.

A Comparative Analysis of Bluetooth BLE and UWB for Real-Time Tracking Systems

This paper explores the advantages of BLE compared to UWB for real-time tracking systems, considering factors such as power consumption, cost-effectiveness, accuracy, scalability, and ease of integration.