About Intensecomp

Intensecomp Pte Ltd is a leading technology company specializing in RFID solutions, warehouse management systems, and asset tracking technologies.

Based in Singapore, we serve businesses across Southeast Asia with innovative solutions including Inventrack WMS, RFID hardware, and integrated IoT sensors.

Our Solutions

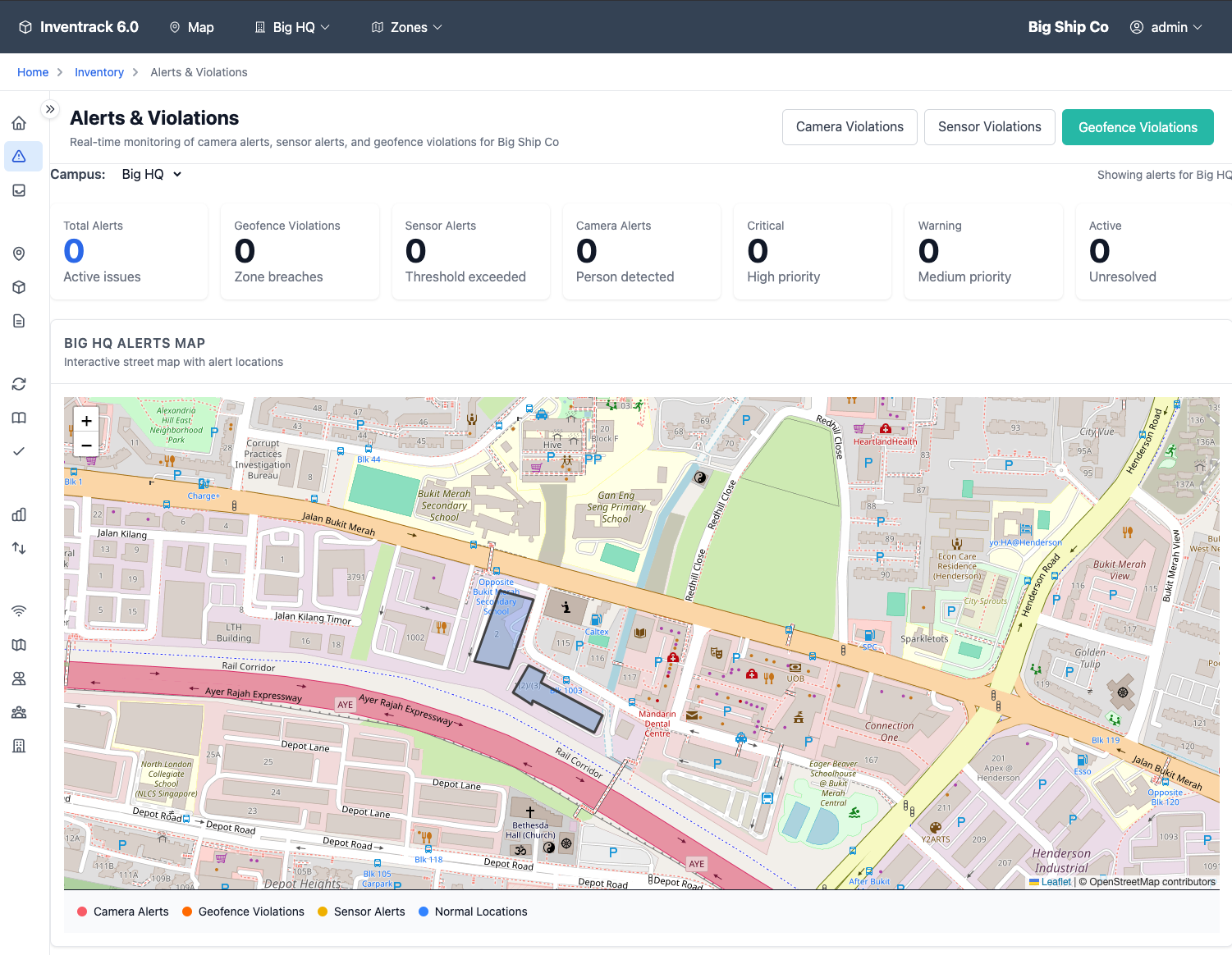

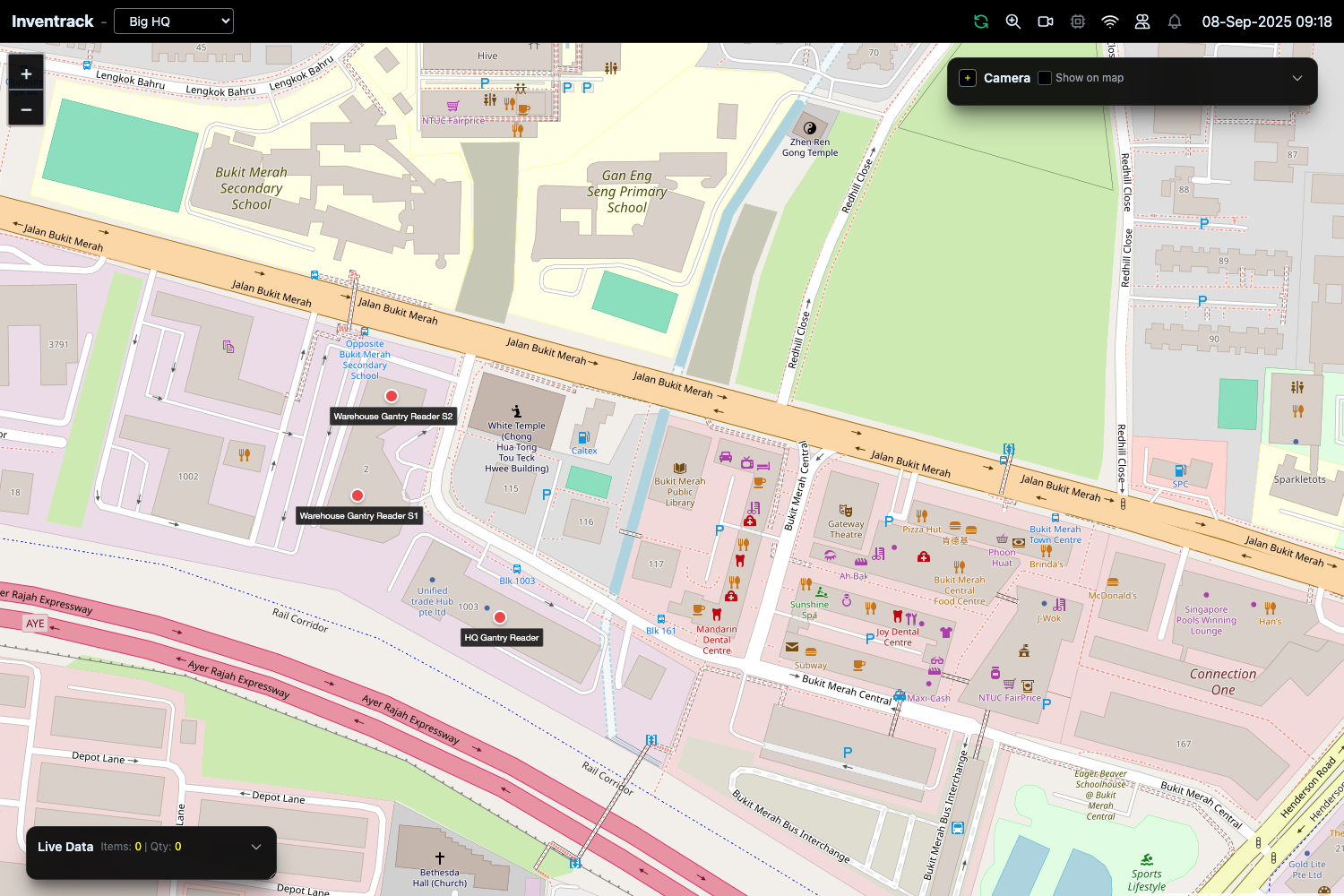

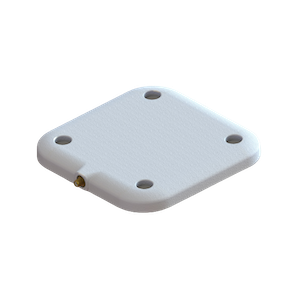

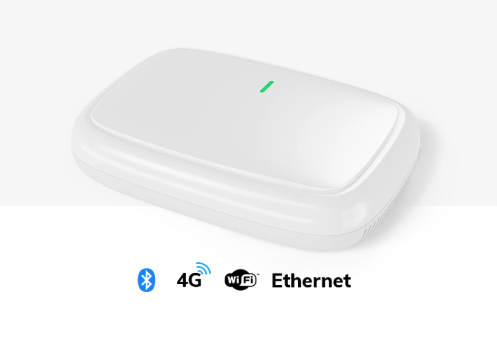

We provide comprehensive warehouse automation including RFID tracking, pick-by-light systems, e-paper displays, robotic AGV integration,

LoRaWAN/BLE/UWB sensors, and camera vision systems. Our flagship product, Inventrack 6.0, unifies all technologies into one powerful platform.

Keywords: RFID Singapore | Warehouse Management System | Asset Tracking | Inventory Management |

Chemical Tracking System | SDS Management Software | Safety Data Sheet Database | GHS Compliance System |

Chemical Inventory Management | Hazardous Material Tracking | Chemical Regulatory Compliance |

Singapore EPMA Compliance | Malaysia OSHA Requirements | ASEAN Chemical Regulations |

Chemical License Management | Dangerous Goods Permit | Chemical Storage Compliance |

SDS Auto Update | AI SDS Management | Chemical Safety Management | Laboratory Chemical Tracking |

Pharmaceutical Chemical Control | Hospital Chemical Management | Industrial Chemical Compliance |

Chemical Lifecycle Management | Chemical Waste Tracking | Incompatible Chemical Storage |

RFID Chemical Tracking | QR Code Chemical Labels | GHS Label Generation | Secondary Container Labeling |

Chemical Spill Response | Emergency Chemical Information | Chemical Training Records |

21 CFR Part 11 Compliance | Controlled Substance Tracking | Cytotoxic Drug Management |

Pick by Light | E-Paper Display | AGV Robots | LoRaWAN Sensors | Computer Vision |

Cold Chain Monitoring | HACCP Compliance | GMP Compliance | Temperature Monitoring |

3PL Warehouse | Multi-Tenant WMS | Cross Docking | FIFO FEFO Management |

Predictive Maintenance | Self Service Kiosk | RFID Portal | Handheld Scanner |

Industry 4.0 | Smart Factory | Cloud WMS | SaaS Platform | Edge Computing |

Cycle Counting | Stock Reconciliation | Order Fulfillment | Reverse Logistics