LoRaWAN Cold Chain Monitoring: Preventing Million-Dollar Losses in Pharma Warehouses

Temperature excursions in pharmaceutical storage can destroy entire shipments. Learn how LoRaWAN sensors combined with RFID tracking create an unbreakable cold chain monitoring system.

The Stakes: When Temperature Kills Inventory

In pharmaceutical distribution, a single temperature excursion can destroy millions of dollars in inventory. Vaccines, biologics, and temperature-sensitive medications require continuous monitoring from manufacturer to patient — the cold chain must never break.

Yet breakdowns happen with alarming frequency:

- A warehouse door left open during a shift change

- A cooling unit failure at 3 AM with no one monitoring

- A power outage during weekend hours

- Temperature sensors placed at the room level missing hot spots near the ceiling

The World Health Organization estimates that up to 50% of vaccines are wasted globally each year, with temperature excursions being a leading cause. For a regional pharmaceutical distributor, a single compromised cold room can mean SGD 2–5 million in destroyed inventory plus regulatory consequences.

Why Traditional Monitoring Falls Short

Most cold storage facilities rely on wired temperature loggers or Wi-Fi-based sensors. These have critical limitations:

- Wired systems are expensive to install and impossible to relocate

- Wi-Fi sensors have limited battery life and struggle with range in metal-heavy warehouse environments

- Point sensors (one per room) miss micro-climate variations — the temperature at floor level can be 3°C different from the ceiling

- Manual log reviews mean excursions are discovered hours or days after they occur

The LoRaWAN Advantage

LoRaWAN (Long Range Wide Area Network) sensors solve these problems with a unique combination of capabilities:

Exceptional Battery Life: A single CR2450 coin cell powers a LoRaWAN temperature sensor for 3–5 years with readings every 5 minutes. No wiring, no charging stations, no maintenance headaches.

Massive Range: A single LoRaWAN gateway covers an entire warehouse campus — up to 2 km indoors and 15 km line-of-sight. One gateway can handle thousands of sensors simultaneously.

Low Cost Per Point: At USD 15–30 per sensor, you can afford to deploy dozens per cold room rather than one or two per room. This enables 3D temperature mapping that catches micro-climate variations.

Metal-Friendly: LoRaWAN’s sub-GHz frequencies penetrate metal racking and concrete walls far better than 2.4 GHz Wi-Fi or BLE signals.

Inventrack’s Integrated Cold Chain Solution

Inventrack 6.0 combines LoRaWAN environmental monitoring with RFID inventory tracking to create a complete cold chain solution:

Layer 1 — Environmental Monitoring (LoRaWAN)

- Temperature sensors at multiple heights in each cold room

- Humidity sensors for moisture-sensitive products

- Door open/close sensors for access tracking

- Power monitoring to detect cooling failures early

Layer 2 — Inventory Tracking (RFID)

- RFID tags on each pallet/case with batch number and expiry

- Portal readers at dock doors track movement in and out

- Handheld scanners for putaway and picking verification

- Automatic FIFO enforcement based on expiry dates

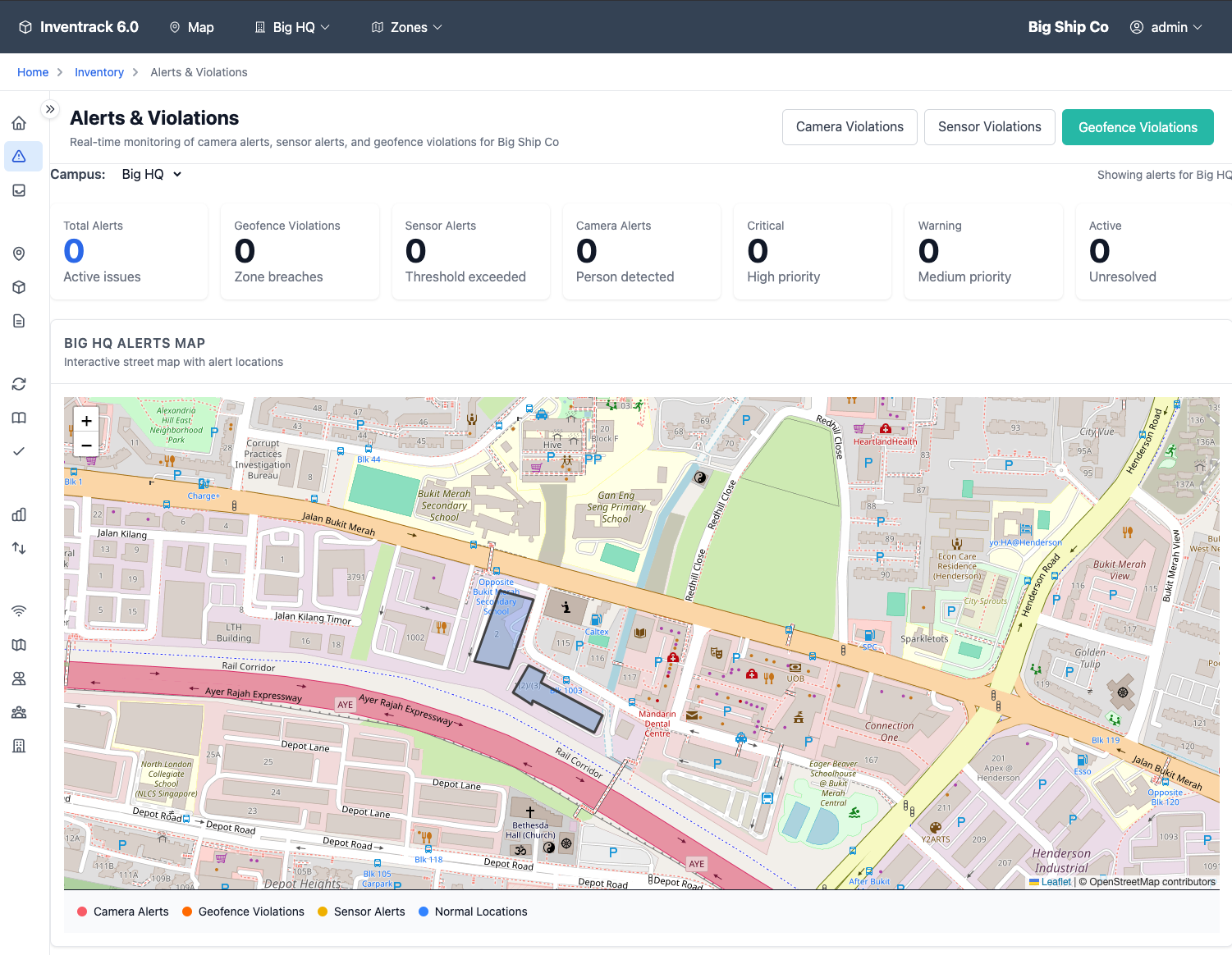

Layer 3 — Intelligent Alerts When a temperature excursion is detected:

- Instant alert to warehouse manager and quality team (push notification + SMS)

- Camera snapshot automatically captured (if vision system is deployed)

- Affected inventory identified — Inventrack cross-references which RFID-tagged pallets are in the affected zone

- Quarantine workflow triggered — affected inventory is flagged, preventing picking until QA clearance

- Regulatory report auto-generated — timestamped evidence package for GMP compliance

Deployment Case Study: Regional Pharma Distributor

A pharmaceutical distributor operating across Singapore and Malaysia deployed Inventrack with LoRaWAN monitoring across 4 cold storage facilities:

Deployment:

- 180 LoRaWAN temperature/humidity sensors (45 per facility)

- 4 LoRaWAN gateways (1 per facility)

- RFID portals at 12 dock doors

- 3,000+ RFID-tagged pallet positions

Results after 12 months:

- Temperature excursion response time: 4+ hours → under 8 minutes

- Product losses from temperature events: SGD 3.1M/year → SGD 120K/year (96% reduction)

- Audit preparation time: 2 weeks → 1 day (automated reporting)

- GMP compliance score: 87% → 99.4%

- ROI achieved: Month 3

The most impactful change was the granular sensor placement. By deploying sensors at floor, mid-rack, and ceiling heights, they discovered persistent hot spots near the ceiling in two facilities that their single-point monitoring had never caught. Fixing the air circulation in those zones alone prevented an estimated SGD 800K in annual product losses.

Implementation Best Practices

Based on our experience across dozens of cold chain deployments in Southeast Asia:

- Sensor density matters more than sensor quality — 20 basic sensors beat 5 premium sensors for spatial coverage

- Place sensors where problems hide — near doors, at ceiling height, behind compressor exhaust

- Set multi-tier alert thresholds — warning at +2°C above target, critical at +5°C, emergency at +8°C

- Integrate with your WMS — knowing what inventory is affected is as important as knowing the temperature

- Test your alert chain monthly — a perfect sensor system is useless if the SMS gateway is down

The Regulatory Landscape

Regulators across ASEAN are tightening cold chain requirements. Singapore’s HSA, Malaysia’s NPRA, and Thailand’s FDA increasingly require continuous digital temperature records rather than periodic manual logs. Organizations that deploy comprehensive monitoring now will be ahead of the compliance curve.

Protecting your cold chain is protecting your business. Contact Intensecomp to discuss a LoRaWAN monitoring deployment tailored to your facilities.

Ready to Transform Your Operations?

Discover how Intensecomp's RFID and IoT solutions can streamline your asset management.

Share this article

Related Articles

The Challenges of Managing Cold Storage Warehouses Compared to Ambient Warehouses

Managing cold storage warehouses presents unique challenges such as maintaining strict temperature controls and regulatory compliance, but these can be effectively addressed with advanced Warehouse Management Systems like Inventrack WMS, which enhance monitoring, inventory management, and operational safety.

How UWB Technology is Revolutionizing Indoor Asset Tracking in 2026

Ultra-Wideband (UWB) tracking delivers centimeter-level accuracy indoors. Discover how UWB combined with RFID is transforming warehouse operations, manufacturing floors, and healthcare facilities.

Understanding Linear and Vertical Polarized Antennas in UHF RFID Applications

Linear and Vertical Polirized Antennas.